Copyright © 2024 SPECIAL METALS. All Rights Reserved.

Nimonic 90 Rod Suppliers, Stockist In India

Request For Our Latest Prices On Nimonic 90 Rod, Alloy 90 Rods in India!

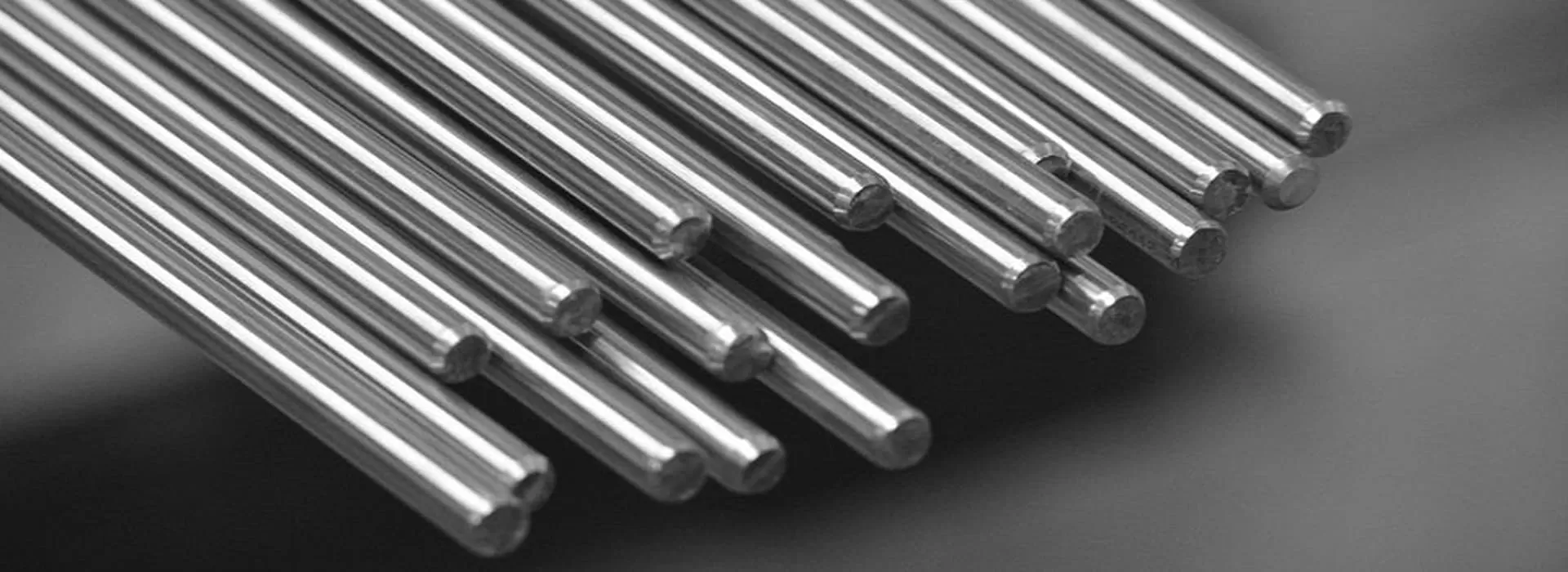

Special Metals offer a comprehensive range of NIMONIC 90 ROD specifications in several applications. It is Nickel, Cobalt, and Chromium composition material with excellent properties. These rods benefit from the age-hardened structure due to NIMONIC 90 material. These rods are widely used in several applications that require enhanced properties.

Nimonic 90 Rods Suppliers, Nimonic Alloy 90 Rod, Alloy UNS N07090 Rod, Nimonic Alloy 90 Round Rods Distributor, Nimonic 90 Rod, 2.4632 Rods Dealer, Alloy 90 Threaded Rod, Nimonic 90 Hex Rod Stockist, Nimonic 90 Rods Supplier In Mumbai, India.

Table Of Content

- What is Nimonic 90 Rod

- Nimonic 90 Rod Specifications

- Nimonic 90 Rod Equivalent Grades

- Nimonic 90 Rod Types

- Nimonic 90 Round Rod

- Nimonic 90 Hex Rod

- Nimonic 90 Threaded rod

- Nimonic 90 Square Rod

- Nimonic 90 Rectangular Rod

- Nimonic 90 Forged Rod

- Nimonic 90 Rod Sizes

- Nimonic 90 Rod Weight Chart

- Chemical Composition of Nimonic 90 Rods

- Mechanical Properties of Nimonic 90 Rods

- Ready Stock of Nimonic 90 Rod in India

- Nimonic 90 Rod Application Industries

- People Also Searched for

Properties of NIMONIC 90 ROD:

- Strength

- Creep-resistance

- Stress Rupture Strength

- Higher Temperature Working

- Corrosion Protection

NIMONIC 90 ROD is created in diverse specifications and standards. We offer durable rods with excessive hardness properties. It is acid corrosion protected in several surroundings. It also resists chloride pitting and general rusting of the surface. Our rods are further employed to heat systems with oxidation confrontation. A combination of hardness and creep resistance helps the rod to withstand extreme heat. Also, the stress applied to the rod is better protracted without cracking.

NIMONIC 90 is a nickel, chromium alloy enhanced with cobalt addition that endows with surface protection quality. Similarly, Titanium and Aluminium is added for improvement of strength and corrosion properties. Cobalt also increases wear resistance and makes it tougher. The grade is extensively picked for precipitation-harden alloy. It endures a large span of work.

NIMONIC 90 ROD is extended to utilize in:

- Gas turbine

- Exhaust valves

- Nuclear boiler

- Die-casting

NIMONIC 90 ROD is erosion conflicted in marine water and protected from chloride and bio attacks. It also avoids other oxidizing, Nitriding effects at higher temperatures and warm surroundings. These rods are hot rolled for several applications, whereas satin coated form in some applications. It is also finished with cold-rolled if required. Various arc-welding methods connect these rods with excellent weldability. Our rods offer greater tensile strength to avoid rupture consequences. Industries utilizing these rods acquire several forms as threaded- either or both ends and welded type with plain or rounded structure. NIMONIC 90 ROD mingle outstanding properties of hardness, ductility, and machinability. Our rods are accurately dimensioned and precisely finished with quality performance in many applications. It is included in automobile, aviation, and Oil & Gas Processing. Also, these rods are preferred in higher heat applications such as hot-working tools, gas turbines, Nuclear industry, Power Generation.

Nimonic® Alloy 90 Rectangle Rods, Nimonic 90 Cold Rolled Rods, Nimonic Alloy UNS N07090 Hot Rolled Rod, Alloy 2.4632 Round Rods, Nimonic 90 Rod Suppliers, Nimonic Alloy 90 Forged Rods, Nimonic 90 Square Rods, Nimonic 90 Rods Stockist in Mumbai.

One of the top most Suppliers and stockists of Nimonic 90 Rods, wholesaler of Nimonic Alloy 90 Rod in Mumbai, Dealers of Nimonic 90 Round Rods, Hex or Square Rod, Stockholder of Nimonic 90 Rod, 90 Nimonic alloy Rod in a variety of thickness, width, or diameter, length and dimension

Nimonic 90 Rod Specification

Dimensions : EN, DIN, JIS, ASTM, BS, ASME, AISI, ASTM, ASME

Size : 5 mm To 500 mm

Length : 9 – 12 metres

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Finish : Cold drawn, Bright drawn, Centreless ground, Cold finished, Peeled and turned, Smooth turned, Slit rolled edge, Hot finished, Hot rolled, Rough turned/peeled, Peeled and reeled

Tolerance : H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

Size : 5 mm To 500 mm

Length : 9 – 12 metres

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Finish : Cold drawn, Bright drawn, Centreless ground, Cold finished, Peeled and turned, Smooth turned, Slit rolled edge, Hot finished, Hot rolled, Rough turned/peeled, Peeled and reeled

Tolerance : H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

Nimonic 90 Rod Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS |

| Nimonic 90 | 2.4632 | N07090 |

Nimonic 90 Rod Types

Nimonic 90 Rod

- Nimonic 90 Rod in Mumbai India

- Nimonic Alloy 90 Round Rods

- 90 Nimonic Rods Dealer

- Nimonic 90 Round Rod Distributor

- Nimonic Alloy 90 Rods Stockist

- UNS N07090 Round Rods Supplier

- Nimonic Alloy 2.4632 Rod Exporter

- Alloy 90 Round Rods Trader in Mumbai India

Nimonic 90 Hex Rod

- Nimonic 2.4632 Hex Rods Dealer

- Nimonic Alloy 90 Hex Rods

- Nimonic Alloy 90 Hex Rods Stockist

- Nimonic N07090 Hex Rods Supplier

- Nimonic Alloy 90 Hex Rods Stockist

- Nimonic 90 Hexagon Rod Distributor

- Nimonic 90 Hexagon Rod Distributor

- 90 Nimonic Hex Rods Dealer

Nimonic 90 Threaded Rod

- Nimonic Alloy 90 Threaded Rods

- 90 Nimonic Threaded Rods Dealer

- Nimonic Alloy N07090 Threaded Rods Supplier

- Alloy 90 Threaded Rods Trader in Mumbai India

- Nimonic Alloy 90 Threaded Rod Stockist

- Nimonic 2.4632 Threaded Rod Exporter

- Nimonic 90 Threaded Rod in Mumbai India

Nimonic 90 Square Rod

- Nimonic® Alloy 90 Square Rod Stockist

- Nimonic UNS N07090 Square Rods Supplier in Mumbai India

- Nimonic Alloy 90 Square Rods Distributor

- Alloy 2.4632 Square Rod Trader

- 90 Alloy Square Rod in Mumbai India

- Nimonic 90 Square Rod Exporter

Nimonic 90 Rectangle Rod

- Nimonic 90 Rectangular Rod Exporter in Mumbai

- Nimonic 2.4632 Rectangular Rod Trader in Mumbai India

- Nimonic® Alloy 90 Rectangle Rods Stockist in India

- 90 Alloy Rectangular Rod in Mumbai India

- Nimonic Alloy 90 Rectangular Rods Distributor in India

- Nimonic UNS N07090 Rectangle Rod Supplier in India

Nimonic 90 Forged Rod

- 90 Alloy Forged Rod in Mumbai India

- Nimonic® Alloy 90 Forged Rod Stockist in India

- 90 Nimonic Alloy Forged Rod in Mumbai India

- Nimonic 90 Forged Rod Exporter in Mumbai

- Nimonic 2.4632 Forged Rods Supplier in India

- Nimonic UNS N07090 Forged Rods Supplier in India

Nimonic 90 Rod Sizes

| Size and Dimensions of Nimonic 90 Rod | |||||||

|---|---|---|---|---|---|---|---|

| Metric | US Rods | ASTM/ Canadian | Japanese | ||||

| Rods Size | Diam. (mm) | Rods Size | Diam. (Inch) | Rods Size | Diam. (mm2) | Rods Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.600 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.600 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

Specialized In Nimonic 90 Rods Stockist In India, Excellent Quality In Nimonic 90 Rod Dealer In India, Get Custom Size Nimonic Alloy 90 Rod at Lowest Price.

Nimonic 90 Rod Weight Chart

| Round Rod | ||||||||

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

Chemical Composition of Nimonic 90 Rod

| Grade | Ni | Cr | Co | Ti | Al | C | Si | Cu | Fe | Mn | B | S | Zr | Pb |

| Nimonic 90 | Bal | 18-21 | 15-21 | 2-3 | 1-2 | 0.2 max | 1.0 max | 0.2 max | 1.5 max | 1.0 max | 0.02 max | 0.015 max | 0.15 max | 0.0020 max |

Mechanical Composition of Nimonic 90 Rod

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 1150 MPa | 725 MPa | 30% |

Ready Stock of Nimonic 90 Rod in India

| Nimonic 90 Rod in Mumbai | Nimonic Alloy 90 Hot Finished Rod |

| Hot-Rolled Nimonic Alloy N07090 Rod | 90 Nimonic Hexagonal Rod Stock |

| Nimonic® Alloy 90 Hexagon Rod | 90 Nimonic Alloy Hot Rolled Rod |

| Nimonic Alloy 90 Half-Rods Supplier | Nimonic® Alloy 90 Rod Stockist in Mumbai |

| Gr 90 Nimonic Rod Suppliers in Mumbai | Nimonic Alloy 2.4632 Rods Exporter |

| Nimonic 90 Rods Supplier in Mumbai | Alloy 90 Bright Rod Trader in India |

| Alloy 90 Threaded Rod | Nimonic Alloy 90 Round Rods Distributor |

| Nimonic Alloy 90 Rod | Nimonic 90 Channel Rod |

| Nimonic Alloy 90 Rods Suppliers | Nimonic Alloy UNS N07090 Rods |

| 90 Nimonic Rods in India | 90 Alloy Rods in India |

| Alloy UNS N07090 Rectangle Rod Dealer | Nimonic 90 Triangle Rod Stockist |

| Nimonic 90 Cold Drawn Rod | Nimonic Alloy 90 Bright Rod |

| Nimonic 2.4632 Black Rods | Nimonic Alloy 90 Hot Rolled Rods |

| Nimonic Alloy 90 Cold Finish Rod | Suppliers of Nimonic Alloy Rod Grade 90 |

| Nimonic 90 Rod at Best Price | Alloy 90 Round Rod Stockists |

Nimonic® 90 Rod Application Industries

- Oil and gas industry

- Pulp and paper industry

- Power plants

- Energy industries

- Modern architecture

- Fluid piping

- Dairy and food processing

- Heat exchanger

- Textile machinery

- Water waste projects

- Synthetic fiber

- Exhaust gas and Exhaust air

- Construction

- Automotive industry

- Transporting materials

People also search for

Nimonic alloy 90 rods at discounted prices, 90 Nimonic rod, Nimonic 90 round rod supplier in mumbai india, Nimonic 90 rod, uns N07090 Nimonic rod supplier in mumbai india, Nimonic 90 rod weight, alloy 90 square rod supplier, Nimonic 90 rods supplier, 90 Nimonic rod trader in mumbai india, Nimonic alloy 2.4632 rod exporter, Nimonic 90 rod near me, 90 Nimonic alloy bright rods, alloy 90 rod, Nimonic 90 rod 16mm, alloy 90 square rods, Nimonic alloy 90 hex rod supplier, Nimonic 90 hexagon rods , Nimonic 90 rod trader in mumbai india, 12mm Nimonic 90 round rods, Nimonic 90 rod, Nimonic 90 rod stock at low prices, Nimonic 90 bright rod supplier, buy Nimonic 90 rectangle rod, Nimonic 90 rod price, alloy 90 rod for sale, 20mm Nimonic 90 rod stock, Nimonic alloy 90 hex rod stockholder, 90 Nimonic alloy hex rod supplier, Nimonic 90 hex rods distributor in mumbai india, bulk stock of Nimonic alloy 90 rods, Nimonic alloy 90 rods stockyard, alloy 90 triangle rod, Nimonic 90 rod suppliers, Nimonic 90 square rod, alloy 90 rods distributor, Nimonic 90 rod in mumbai india, Nimonic 90 rod size, Nimonic alloy 90 rods stockist, Nimonic 90 rod price in india, Nimonic 90 rod length, Nimonic 90 hex rod, Nimonic 90 rod stock, Nimonic 90 cold drawn round rod, Nimonic 90 hex rod wholesaler, 8 mm 90 alloy square rod exporter, Nimonic 90 rod suppliers, 10mm Nimonic 90 round rods exporter, Nimonic 90 rod dimensions, Nimonic alloy 90 rods trader, 90 Nimonic rod sizes in mm, Nimonic alloy 90 rods, alloy 90 square rod distributor in mumbai india.

We Export Nimonic 90 Rod Across the Globe

- MIDDLE EAST : Saudi Arabia, Iran, Ira, Qatar, Bahrain, Oman, Kuwait, Turkey, Yemen, Syria, Jordan, Cyprus

- ASIA : Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Myanmar, Taiwan, Cambodia

- EUROPE : Russia, Norway, Germany, France, Italy, UK, Spain, Ukraine, Netherlands, Belgium, Greece, Czech Republic, Portugal, Hungary Albania, Austria, Switzerland, Slovakia Finland, Ireland Croatia, Slovenia, Malta

- AFRICA : Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, the Republic Of Congo, Gabon

- SOUTH AMERICA : Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay

- NORTH AMERICA : US, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark

Material

- Molybdenum Products

- TZM Products

- Nitinol Products

- Titanium Products

- Tungsten Copper Products

- Beryllium Copper Products

- Tantalum Products

- Tungsten Products

- Indium Products

- Inconel Products

- Monel Products

- Hastelloy Products

- Stainless Steel Products

- Alloy 20 Products

- Lead Products

- Zinc Products

- SMO 254 Products

- Niobium Products

- Vanadium Products

- Nimonic Products

- Aluminium Products

- Brass Products

- Naval Brass Products

- Invar Products

- Kovar Products

- Nickel Products

- Other Products

We touch the lives of millions of people across the world every day with the steel that we produce.

Address

125, C.P. TANK ROAD, NEAR MADHAVBAUG TEMPLE, SHOP NO 10, MUMBAI - 400004 , INDIA