Copyright © 2024 SPECIAL METALS. All Rights Reserved.

Request For Our Latest Prices On Hastelloy X Rods, ASTM B572 Alloy X Rod in India!

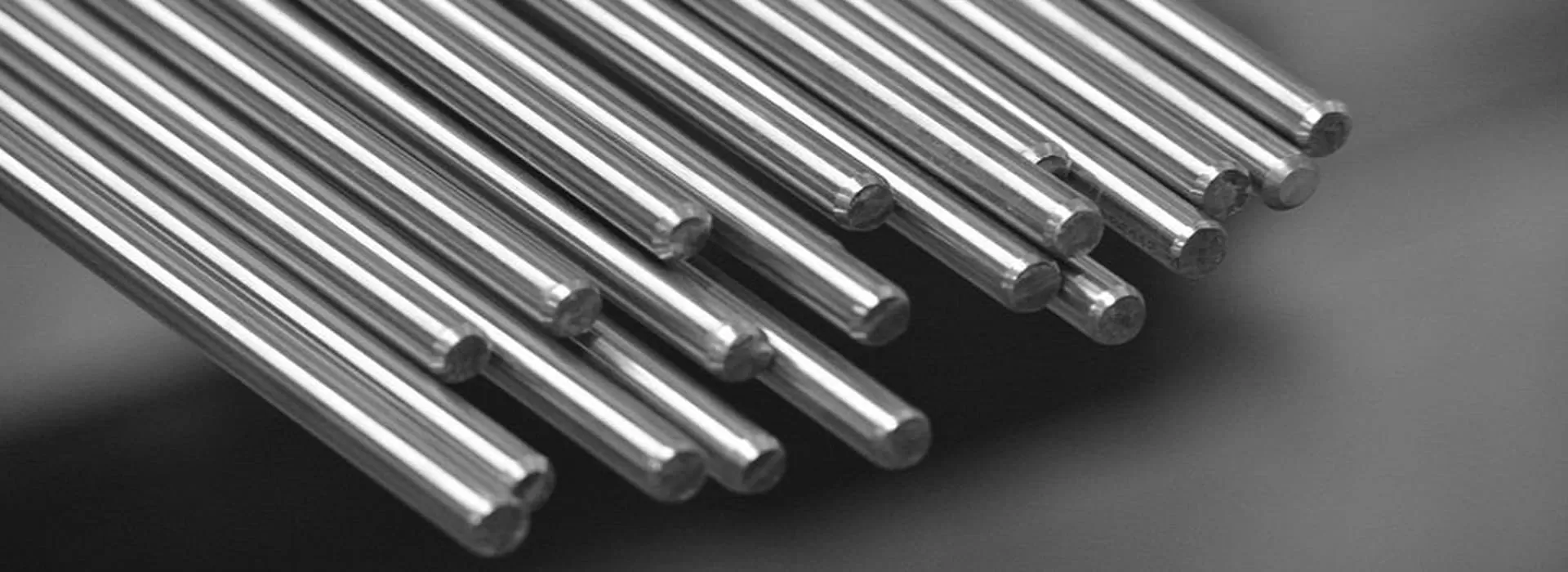

Special Metals is engaged in manufacturing superior quality HASTELLOY X ROD in a large variety. We offer multiple specifications and dimensions of these rods. Our rods offer excellent strength in various heat applications as it shows outstanding heat resistance. In addition, These rods are availed in diverse forms with excellent grade properties. It is made up of HASTELLOY X alloy to enhance characteristics in corrosive environments. Its higher toughness is supportive to high-temperature tolerance. These rods come together with amplified strength, Oxidation resistivity, and cracking prevention. Therefore longer use of the rods is beneficial with relative cost.

HASTELLOY X alloy is known as superalloy since it unites several thermal and resistive properties with an excellent strength increase. Nickel, Chromium, Molybdenum, Titanium, and Iron are super quality metals composed to form HASTELLOY X grade and other elements. It is enriched with strength in high-temperature stability and various corrosion prevention.

Consequently, HASTELLOY X ROD is an excellent performing rod with properties like:

Table Of Content

- What is Hastelloy X Rod

- Hastelloy X Rod Specifications

- ASTM B572 Hastelloy X Rod Equivalent Grades

- Hastelloy X Rod Types

- Hastelloy X Round Rod

- Hastelloy X Hex Rod

- Hastelloy X Threaded rod

- Hastelloy X Square Rod

- Hastelloy X Rectangular Rod

- Hastelloy X Forged Rod

- Hastelloy X Rod Sizes

- Hastelloy X Rod Weight Chart

- Chemical Composition of Hastelloy X Rods

- Mechanical Properties of Hastelloy X Rods

- Ready Stock of Hastelloy X Rod in India

- Hastelloy X Rod Application Industries

- People Also Searched for

HASTELLOY X ROD is easily formable in hex, round, square, threaded, and flat shapes. We offer rods of various surface finishes to prevent corrosion effects. These rods are connected as welded or threaded connections with either or both ends. General corrosion and pitting is avoided with excellent resistance. Additionally, the rod is impervious in several reducing media that contains acids and chlorides. Thus chloride-ion splitting effect is incapable of affecting the rod. Higher temperatures applied on the rod turns to stress cracking, whereas it is protected with the tensile strength of the rod and improved heat corrosion resistance.

HASTELLOY X ROD is the best performing in neutral and nitriding atmospheres. It is excellent tensile to face higher stress. These rods are also protected in a large range of higher temperatures with efficient working. We offer rods with excellent durability and heavy-duty performance. These rods are hardened with Molybdenum content that supports matrix stiffening. Carburization and nitriding are resisted with the excellent immune property of the rod that avoids early failure at higher temperatures.

We offer extensive use of HASTELLOY X ROD in:

Specifications : ASTM B572 / ASME SB572

Dimensions : EN, DIN, JIS, ASTM, BS, ASME, AISI, ASTM, ASME

Size : 5 mm To 500 mm

Length : 9 - 12 metres

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Finish : Cold drawn, Bright drawn, Centreless ground, Cold finished, Peeled and turned, Smooth turned, Slit rolled edge, Hot finished, Hot rolled, Rough turned/peeled, Peeled and reeled

Tolerance : H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | EN |

| Hastelloy X | 2.4665 | N06002 | HR 204 | NC 22 FeD | NiCr22Fe18Mo |

| Size and Dimensions of Hastelloy X Rod | |||||||

|---|---|---|---|---|---|---|---|

| Metric | US Rods | ASTM/ Canadian | Japanese | ||||

| Rods Size | Diam. (mm) | Rods Size | Diam. (Inch) | Rods Size | Diam. (mm2) | Rods Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.600 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.600 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Round Rod | ||||||||

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

| Grade | C | Mn | S | Si | Ni | Cu | Fe |

| Hastelloy X | 0.05-0.15 | 1 max | 0.03 max | 1 max | remainder | – | 17-20 |

| Grade | Tensile Strength (MPa) | Yield Strength (0.2%Offset)(MPa) | Elongation % min. |

| Hastelloy X | 690 min. | 283 min. | 40% |

| Hastelloy X ASTM B572 Rod in Mumbai | Nickel Alloy X Hot Finished Rod |

| Hot-Rolled Nickel Alloy N06002 Rod | X Hastelloy Hexagonal Rod Stock |

| Hastelloy® Alloy X Hexagon Rod | X Hastelloy Alloy Hot Rolled Rod |

| Hastelloy Alloy X Half-Rods Supplier | Hastelloy® Alloy X Rod Stockist in Mumbai |

| Nickel Alloy X Rods Suppliers | Hastelloy UNS N06002 Rods |

| X Hastelloy Rods in India | ASME SB572 X Alloy Rods in India |

| Alloy X ASTM B572 Threaded Rod | Hastelloy Alloy X Round Rods Distributor |

| Gr X Hastelloy Rod Suppliers in Mumbai | Nickel Alloy 2.4665 Rods Exporter |

| Hastelloy Alloy X ASTM B572 Rod | Hastelloy X Channel Rod |

| X Hastelloy ASME SB 572 Threaded Rods | Hastelloy X T-Rod Supplier in India |

| Alloy UNS N06002 Rectangle Rod Dealer | Hastelloy X Triangle Rod Stockist |

| Hastelloy X Rods Supplier in Mumbai | Alloy X Bright Rod Trader in India |

| ASME SB572 Hastelloy X Cold Drawn Rod | ASTM B572 Hastelloy Alloy X Bright Rod |

| Hastelloy 2.4665 Black Rods | Hastelloy Alloy X Hot Rolled Rods |

| ASTM B572 Alloy X Cold Finish Rod | Suppliers of Hastelloy Alloy Rod Grade X |

| Hastelloy X Rod at Best Price | Alloy X Round Rod Stockists |

125, C.P. TANK ROAD, NEAR MADHAVBAUG TEMPLE, SHOP NO 10, MUMBAI - 400004 , INDIA

Copyright © 2024 SPECIAL METALS. All Rights Reserved.

125, C.P. TANK ROAD, NEAR MADHAVBAUG TEMPLE, SHOP NO 10, MUMBAI - 400004 , INDIA

Copyright © 2024 SPECIAL METALS. All Rights Reserved.