Vacuum systems need strong seals to keep air out. Indium wire is a soft metal that helps make those seals tight. It’s easy to work with and perfect for delicate jobs. In this blog, you’ll learn how to use indium wire step by step.

Whether you’re setting up a lab experiment or sealing a cryogenic chamber, this guide will help. We’ll also cover why indium wire is popular and where to find trustworthy indium wire suppliers.

What is Indium Wire?

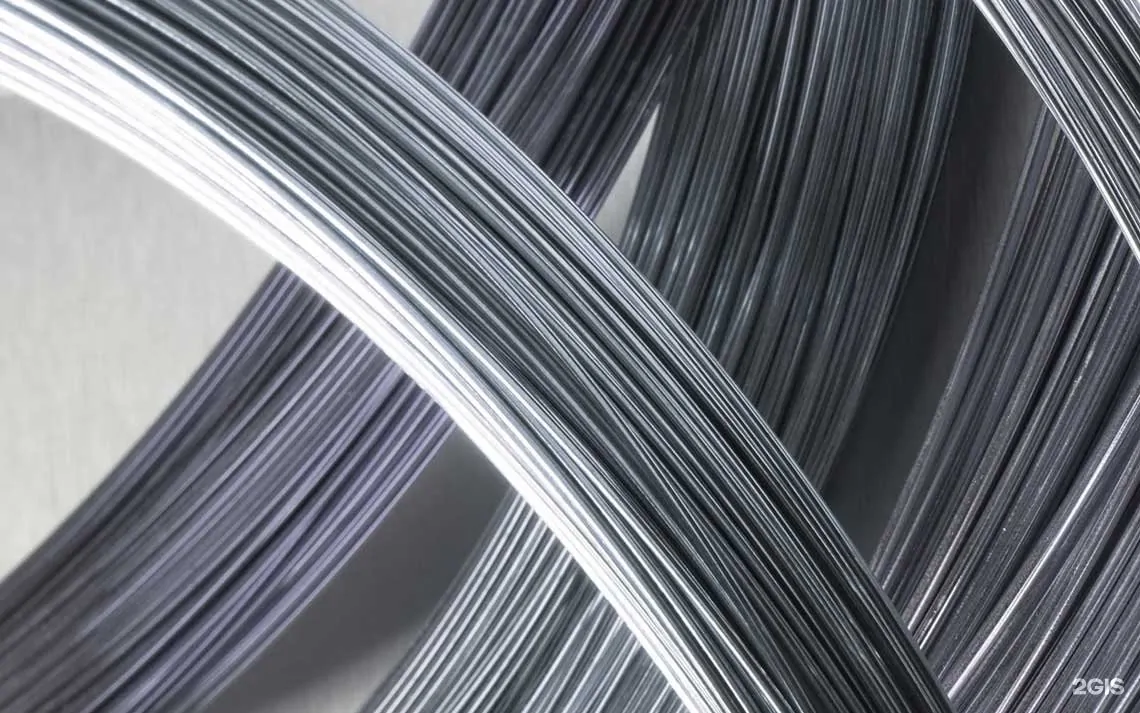

Indium wire is made from pure indium metal. It’s soft, pliable, and sticky at room temperature. That makes it ideal for vacuum sealing. Unlike other metals, indium doesn’t crack when compressed. It gently flows into gaps and remains in place. It forms a seal that blocks gas and moisture. This is why it’s used in vacuum systems, cryogenics, and optics.

Why Use Indium for Vacuum Seals?

- Soft and flexible: It shapes itself to the surface.

- Low outgassing: Doesn’t release gas when used in a vacuum.

- Non-corrosive: Safe with glass, metal, and ceramic.

- No curing needed: It seals right away without heat, or chemicals.

Where to Purchase Indium Wire?

Always buy from reliable indium wire vendors. Opt for high-purity versions (99.99% or better). Vendors should deliver clean, soft wire with no surface defects. Don’t use recycled, or oxidized wire; it will not seal properly.

Certain suppliers have wire in special sizes. You can request certain diameters based on your flange or seal design.

Tools You’ll Need

Do these in advance:

- Indium wire (new and clean)

- Razor blade or wire cutter

- Clean gloves (latex or nitrile)

- Clean cloth or wipes (lint-free)

- Isopropyl alcohol (99%)

- Flanges or sealing surfaces

- Torque wrench or Allen keys

Step-by-Step: How to Use Indium Wire for Vacuum Seals

- Step 1: Sanitize All Surfaces

Sanitize both sealing surfaces using isopropyl alcohol. Wipe them down with a lint-free cloth. Make sure that there is no dust, oil or outdated sealant present. Smooth, clean surfaces are ideal for indium bonding.

- Step 2: Measure and Cut the Wire

The sealing edge should be measured. Cut an extra 5 mm or so of indium wire. This gives you room to press the ends together.

Use a clean blade or wire cutter. Don’t stretch the wire. Stretched indium may crack.

- Step 3: Press the Wire in Place

Place the indium wire around the sealing surface. Lightly press it down with your fingers. The wire should sit flat and even.

When the ends meet, overlap or gently press them together. Avoid gaps. The connection point should be snug.

- Step 4: Align the Flanges

Place the top flange (or other surface) carefully over the wire. Keep it centered. Try not to shift the wire.

If screws are being used, make sure they are inserted evenly. Avoid tightening just yet.

- Step 5: Make sure to tighten evenly

Using a cross pattern, tighten each screw requires less time (like car tires). Indium is uniformly pressed as a result. Don’t overtighten at first.

Once all screws are snug, go back and torque them to the final value. Check your flange or device manual for correct torque.

- Step 6: Check the Seal

After tightening, check the seal visually. The indium should flatten and spread slightly. No part of it should bulge or be missing.

If you’re using a vacuum pump, do a leak check. A proper seal should hold vacuum without drops in pressure.

- Step 7: Reusing the Seal (Optional)

Indium seals are usually one-time use. If you take the system apart, clean off the old wire and replace it.

Never try to reuse indium that’s been compressed. It won’t seal well again.

Tips for Better Seals

- Store indium in a clean, sealed bag. Keep moisture and air out.

- Always wear gloves. Bonding is ruined by finger oils.

- Don’t touch the cut end with bare hands.

- Work in a clean room or dust-free space, if possible.

- Don’t compress too much. Excessive force could cause the wire to break unevenly.

Common Mistakes to Avoid

- Dirty Surfaces: Prior to sealing, always clean.

- Old or reused wire: Use fresh wire every time.

- Uneven tightening: Causes leaks and poor seals.

- Wrong diameter wire: Too thin or thick can fail under pressure.

Applications of Indium Vacuum Seals

- Cryogenic systems

- UHV (Ultra High Vacuum) chambers

- Optical devices

- Glass-to-metal joints

- Custom scientific instruments

Final Thoughts

It is not difficult to use the indium wire for vacuum seals. But you have to be careful about it. You can create safe seals that will work under pressure with clean surfaces, proper equipment and new indium.

If you require pure wire, use reputable suppliers of indium wire. They will assist you to obtain the appropriate size and quality for your job.